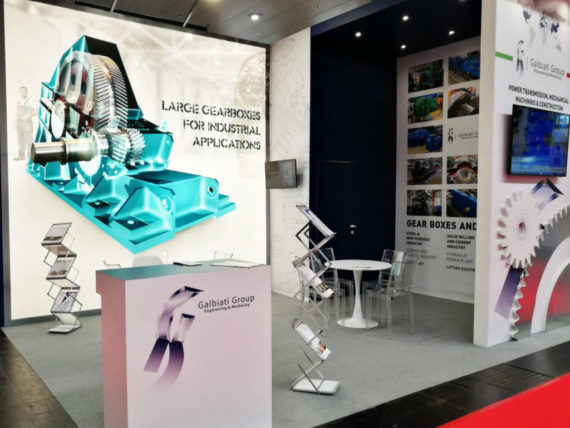

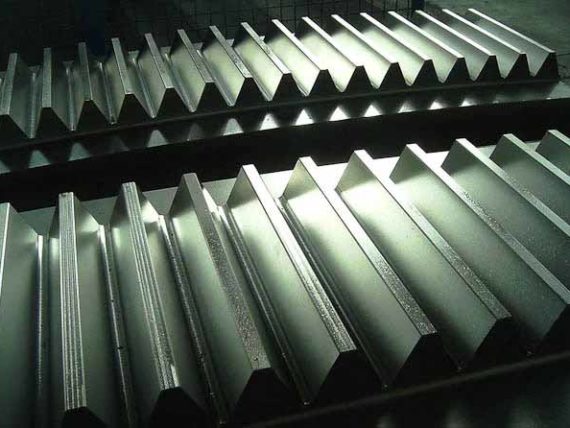

GEAR REDUCERS

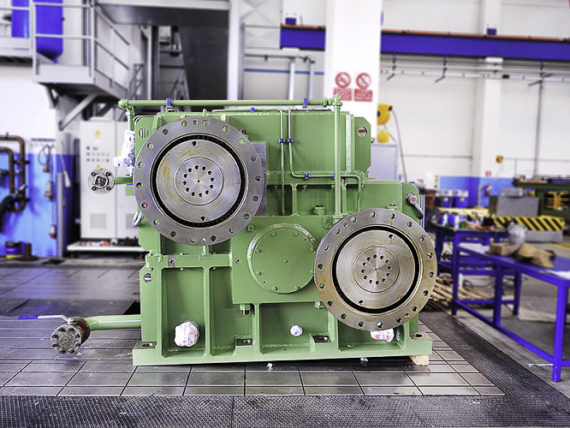

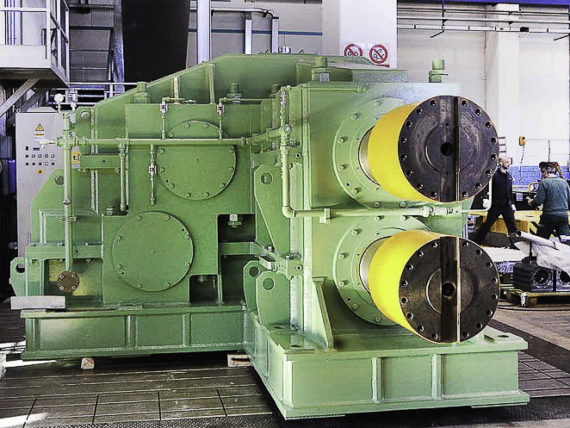

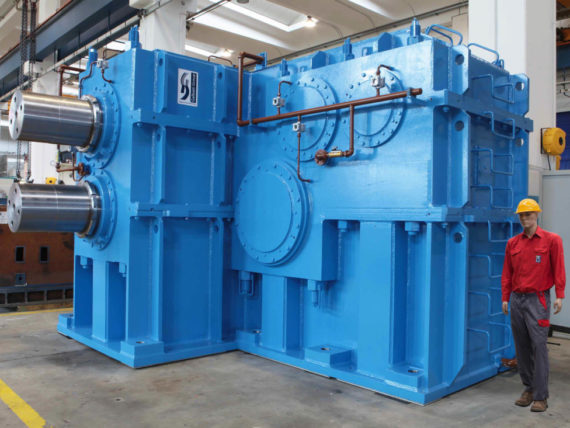

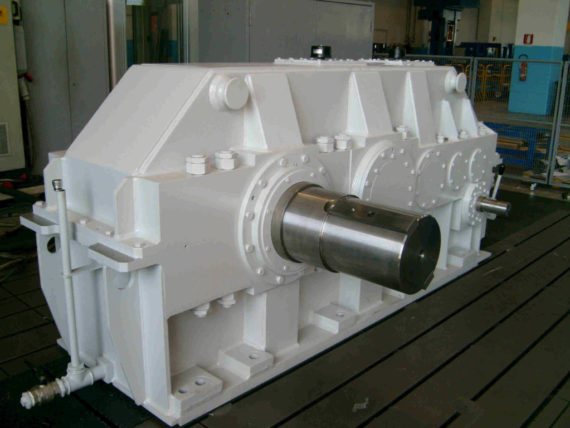

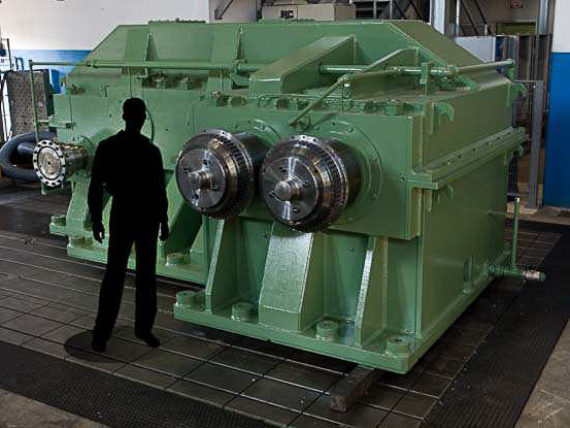

Gear reducers and increasers, mechanical power transmissions for mid- and large-sized industrial applications.

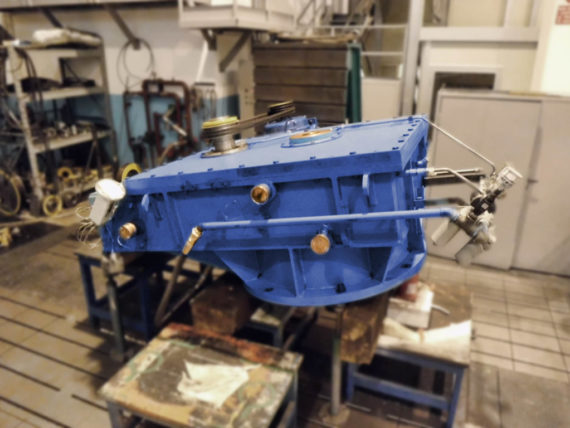

Design, construction, and reconditioning.

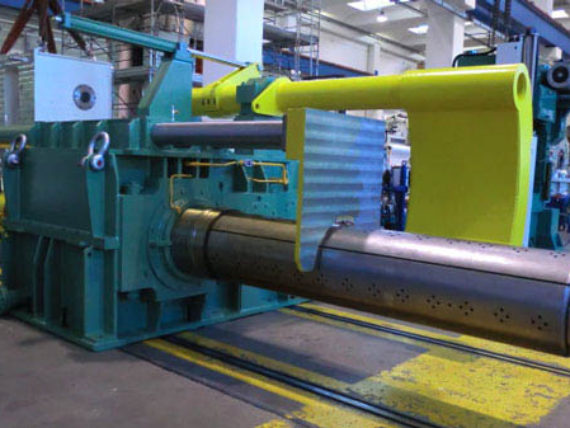

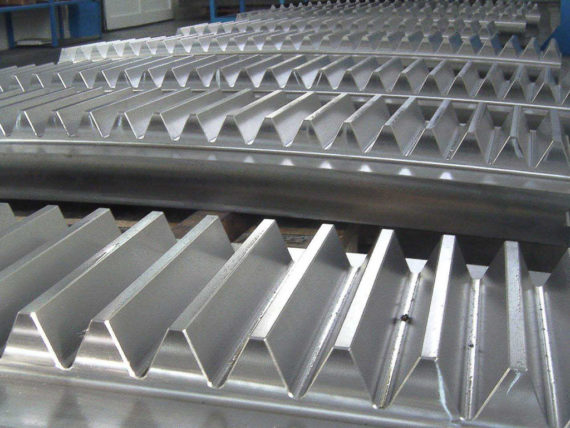

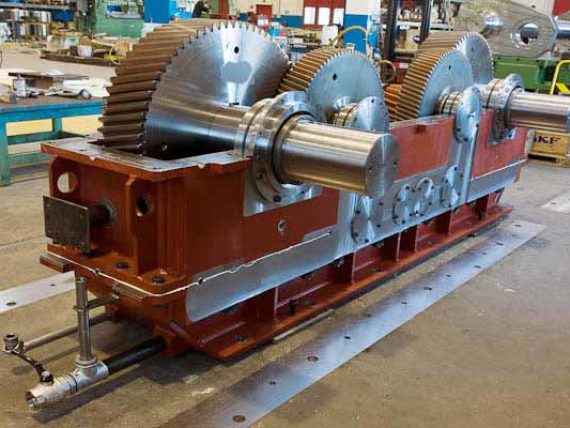

Galbiati Group has extensive experience in the design, manufacturing and revamping of: mechanical transmissions for steel industry (hot and cold rolling mill), large Edger drives, pinion stands and twin drives for mill stands, main drives for shears, tilting converters drives, coilers and uncoilers.

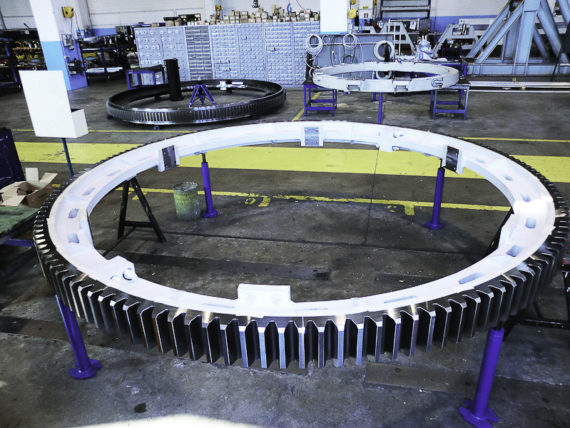

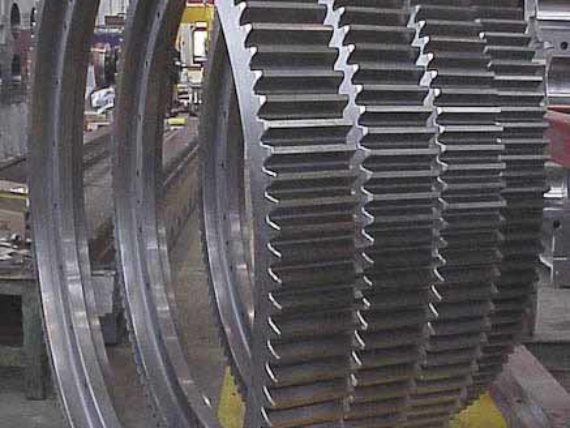

Turbine and pump gearboxes for hydroelectric power plants; planetary drives for antenna actuation and for TBM rotating heads; drives for rubber and plastic mixers; drives for cement industry and solid mills; winch drives for cable-car industry (cable railways, cable ways, cable cars, and chairlifts) and hosting equipment; gears and toothed gear segments for antenna actuation; girth gears for cement mills and kilns; gears for harbor cranes and marine winches; ring gears and pinions for TBM head drives.

Inspections and Certifications

All Galbiati Group gear drives are “full speed – no load” tested for a minimum of six hours. The gear drive performance (lubrication system, temperature probes, etc.) and its accessories (ejectors, hold down rolls, etc.) are properly checked . On each new unit, as well as on the overhauled one, temperatures (oil, housing, and bearings), noise levels, and vibrations are measured and recorded on relevant test record.

A “Certification File” is issued for each drive, which contains the raw materials and all the manufacturing process inspection certificates as well as the final test report.

For more information on quality, please see our dedicated page.

Certified Quality: extreme accuracy without tolerances

Thanks to the three dimensional measuring machine, ZEISS MMZ-G 30 60 25, Galbiati Group is one of the few Italian companies performing inspections on items for applications that require micron-tolerances and issuing proper certifications. In addition to dimensional inspection, the following non-destructive test are performed:

- Magnetic test – MT

- Dye penetrant test – PT

- Ultrasonic test – US

READ MORE

READ ALL POSTS

- Planetary Drives (3)

- Drives for cable car systems and hoisting winches (4)

- Gear drives and gears for cement and solid milling industry (8)

- Gear reducers for chemical reactors (1)

- Drives for metallurgy industry cold mill (8)

- Drives for metallurgy industry Hot mill (15)

- Steel industry drives Converters (3)

- Steel industry Miscellaneous applications (10)

- Shear drives (1)

- Mill drive (4)

- Screw drives (3)

- Tube drawer drive (2)

- Rubber industry drives (8)

- Gears (14)

- Gear increasers (4)

- Gearbox Reconditioning (4)

English

English Italiano

Italiano Deutsch

Deutsch