-

ZEISS

ZEISS

-

ULTRASONIC TEST

ULTRASONIC TEST

-

ULTRASONIC TEST

ULTRASONIC TEST

-

MAGNETIC TEST

MAGNETIC TEST

-

MAGNETIC TEST

MAGNETIC TEST

QUALITY

Q

uality is the result of an organizational / production process, optimized and controlled at every stage, this has allowed Galbiati Group to obtain the certification of its Quality System at the beginning of 1997 in reference to the standard UNI EN ISO 9002, version 1994, which accredited it as the only company qualified as a material manufacturer, installer and service provider.

Afterwards, in 2002, the Company adapted its own structure as shown in the standard update UNI EN ISO 9001, version of 2000, which introduced for the first time the “Process Approach” concept, enabling the company to become a supplier able to deliver products that fully comply with the requirements of the customer, and thus improving customer satisfaction.

Finally in 2009, the Company designed, built and improved its internal processes with respect to the requirements for standard UNI EN ISO 9001, version of 2008, which further clarifies the concept of “processes” listed in the previous UNI EN ISO 9001 version of 2000: The company must determine the processes needed for the Quality Management System, elaborating the sequence, the application, the interaction and ensuring continuous improvement, in order to improve customer satisfaction.

Galbiati Group has implemented in its quality system the transition from the UNI EN ISO 9001- EDITION 2008, where the concept of controlled processes was enunciated, to the new UNI EN ISO 9001- EDITION 2015, that introduces risk analysis concepts.

DIMENSIONAL CONTROL

Certified Quality and Precision

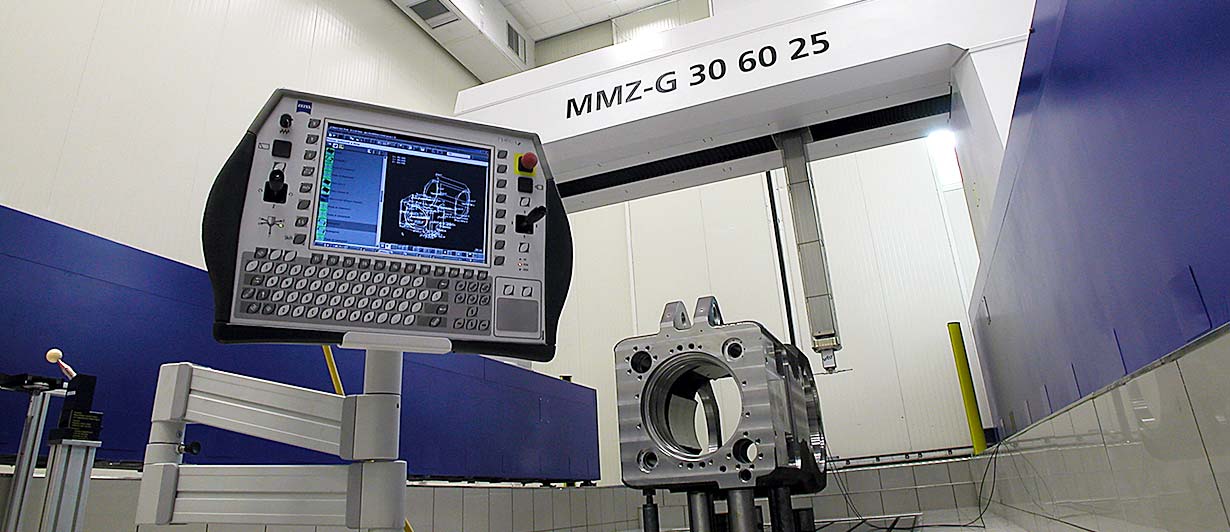

Thanks to its ZEISS MMZ-G 30 60 25 three dimensional coordinate measuring machine (operating range: L 6 m x D 3 m x H 2.5 m) housed in a controlled climate room, the Galbiati Group is among few Italian companies capable of performing inspections on large-sized components for applications requiring an uncertainty of measurements in micron, as well as issuing dimensional certification.

In order to perform controls on small dimension pieces, Galbiati Group uses a ZEISS ACCURA three-dimensional measuring machine with an operating range of 1.8 m Length x 1.2 m Depth x 1.0 m Height in air-conditioned room. In this case, as well, a dimensional certification compliance is released.

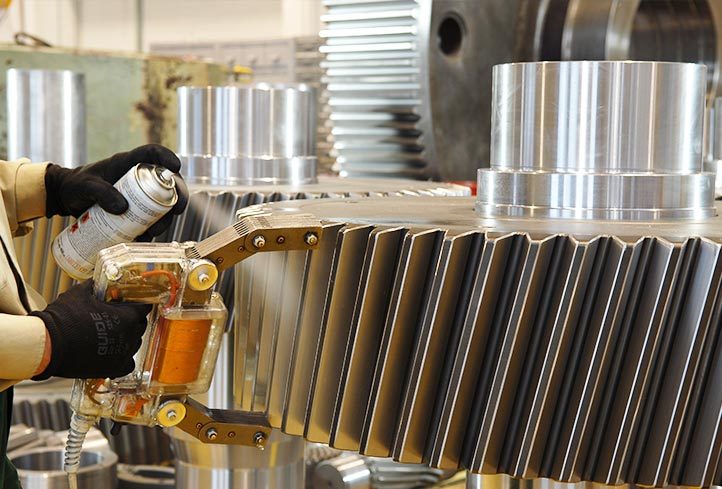

Non-destructive Testing – Material & Product Quality

Apart from dimensional controls, we carry out several non-destructive tests:

- Ultrasonic Test – UT

- Magnetic Test – MT

- Dye Penetrant Test – PT

- Visual Test – VT

CERTIFICATES

Certificates relevant to the implementation of processes and activities in reference to specific regulations

Certification of Quality Management System:

Rule of reference UNI EN ISO 9001:2015 issued by TUV recognized by ACCREDIA.

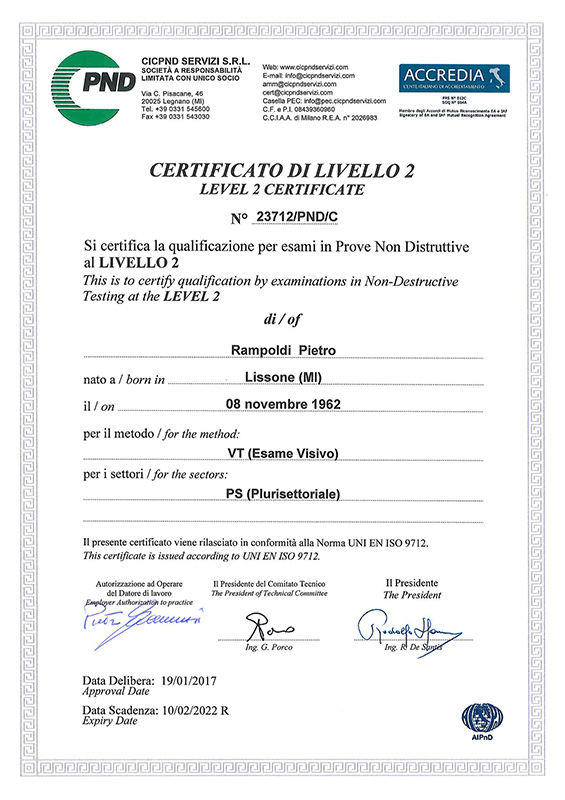

Qualifications to perform non-destructive testing: CND performance in reference to the requirements of the standard ISO 9712 with staff qualifications certified by CICPND, ACCREDIA recognized and valid for testing:

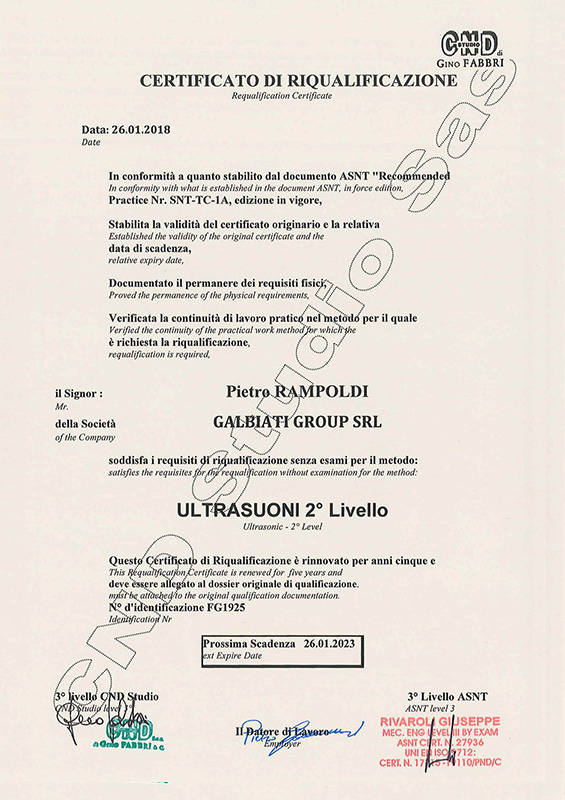

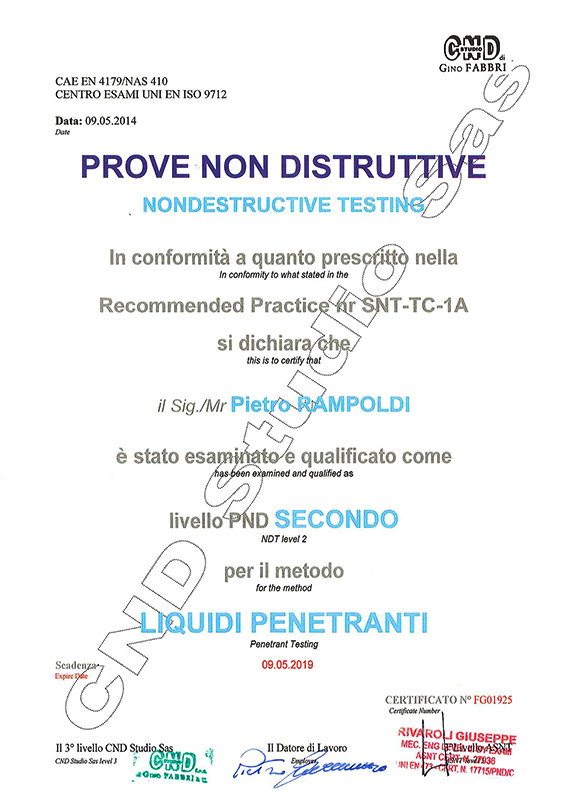

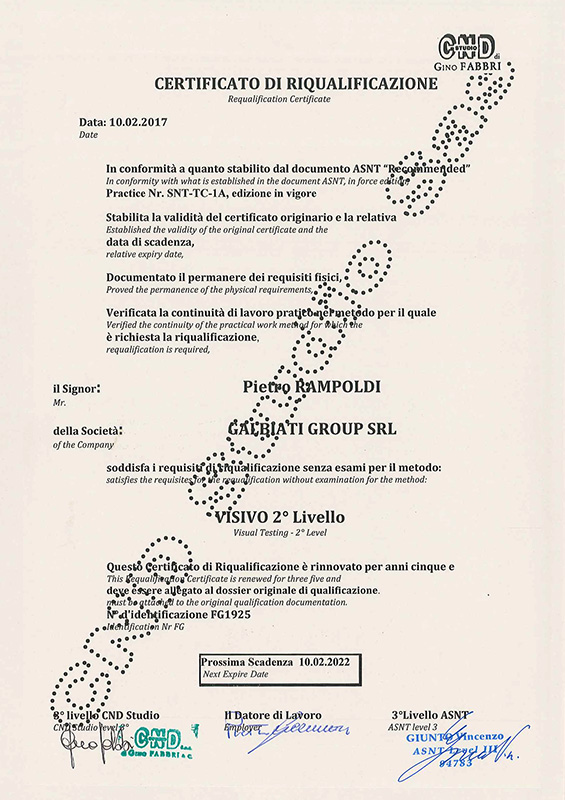

Qualifications to perform non-destructive testing: CND performance in reference to the Recommended Practice no. SNT-TC-1A with staff qualifications certified by CND valid for testing:

To ensure the highest quality, the management of production processes is essential in the critical transit of the company’s manufactured products and in particular:

- Incoming inspection: Incoming materials are inspected to evaluate their compliance with the specifications.

- In-process inspection: Products undergo constant testing during machining and assembly.

- Final inspection of all machined products: Inspection according to the regulations outlined in international standards and in line with all customer specifications.

All controls / tests described are performed by qualified operators in relation to regulations and the issuance of compliance certificates stating that the controls / tests are regulated by the standard UNI EN 10204 for the 2005 edition.

English

English Italiano

Italiano Deutsch

Deutsch