The Galbiati Group recently built a large pinion stand drive as part of a revamp carried out on an existing hot rolling mill at Mariupol, Ukraine.

The engineering process was undertaken by the Galbiati Group in collaboration with Primetals Linz, whilst the pinion stand drive was purchased directly by Metinvest Engineering LLC, Dnipropetrovsk, Ukraine.

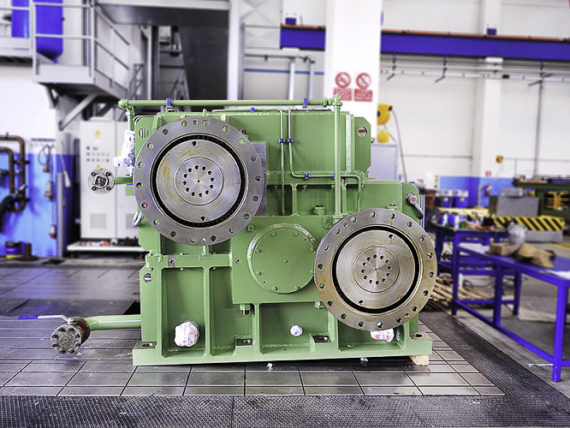

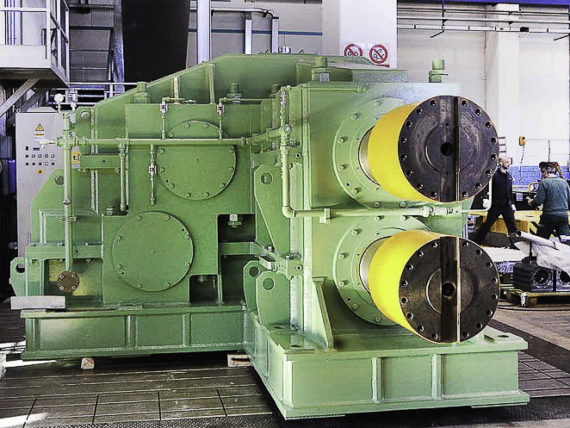

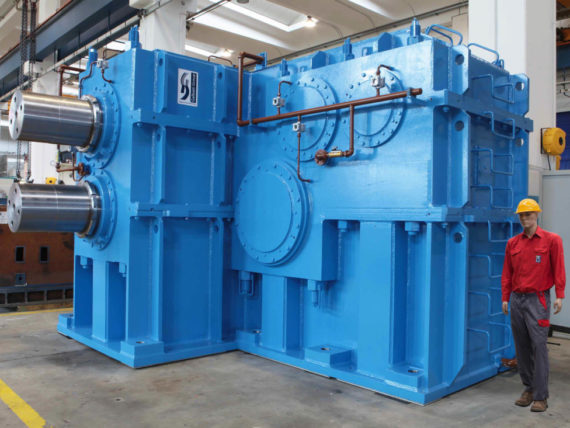

Our supply contract covered the engineering and manufaturing of a large pinion stand drive for a hot rolling mill, equipped with 1 x 7000 kW motor, a single horizontal input shaft and twin output shafts. The gears and shafts consist of double helical pinions made of 18CrNiMo7-6 steel, hardened, casehardened and ground to meet the standards of DIN 3961 grade 6. Gear teeth undergo profile correction to optimize power transmission and contact between mating surfaces of the gear pair. In addition, the pinion shafts are fitted with ring seals designed to prevent wear.

The housing of the pinion stand drive is an electrically welded and stress-relieved structure made of S355J2 carbon steel. It also incorporates generously proportioned inspection windows and an air breather for the levelling of machined surfaces.

The pinion stand drive is fitted with high quality roller bearings mounted in metal cages ideally suited to the specified speeds of rotation.

The housing was sand-blasted and treated with epoxy primer, then coated internally with an oil-resistant paint, and externally with a finish colour as illustrated in the photographs below.

Pinion stand drive technical data:

- Overall weight = 32 tonnes;

- Length = 3800 mm;

- Height = 2686 mm;

- Power = 7000 kW at 200 rpm;

- Centre distance = 690 mm.

All machined parts of the pinion stand drive are treated with Tectyl to guard against corrosion, and guaranteed fully waterproof. The unit is suitably protected and packed in a wooden crate ready for shipment by sea.

Individual components of pinion stand drive are inspected to determine wear and deformation. Non-destructive tests, are conducted by skilled and experienced technicians, using high-precision instruments and a ZEISS MMZ-G 30 60 25 three dimension measuring machine.

Once completed the pinion stand drive, a full-speed running test is performed. Temperatures, noise levels, and vibrations are continuously measured and properly recorded.

A “Certification File” is issued for each drive, which contains the materials and inspection certificates as well as all intermediate and final inspection drive report.

The following pictures show the pinion stand drive during test procedures, and fully assembled in the dedicated area of the Galbiati workshops.

English

English Italiano

Italiano Deutsch

Deutsch