Galbiati Group has recently manufactured a control gear for a converter-winch for the Rourkela steel mill in India.

The control gear for the winch is controlled by two electric motors with a total power output of 264 kW / 1450 RPM.

The slow-running axis rotates at a speed of 7.18/3.02 RPM (the gear ratio is therefore 201/480).

Equipped with a pneumatic auxiliary motor with 38 kW and 1500 RPM, the various final speeds are achieved through the positioning process (controlled by micro switch) with two toothed transmissions and a speed of 0.

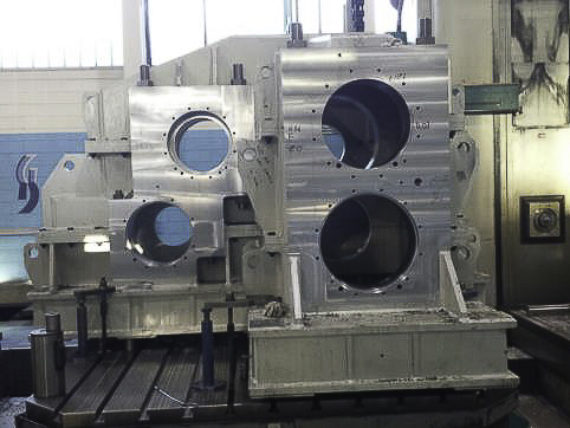

The gearbox is fitted with a welded, annealed, sanded metal housing that was processed on a modern CNC machine tool, of which Galbiati Group owns quite a few.

Toothed wheels with single-screw made of high-quality 18NiCrMo5 steel, cemented with a surface hardness of 58-60 HRC according to the quality standards ISO- DIN 6/7.

The gearbox is equipped with a slow-moving shaft made of molybdenum-alloyed steel as well as high-quality ball bearing designed for a minimal life span of 50,000 hours at full operation and speed.

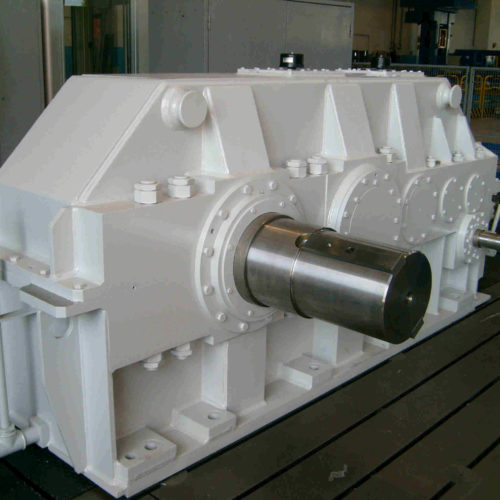

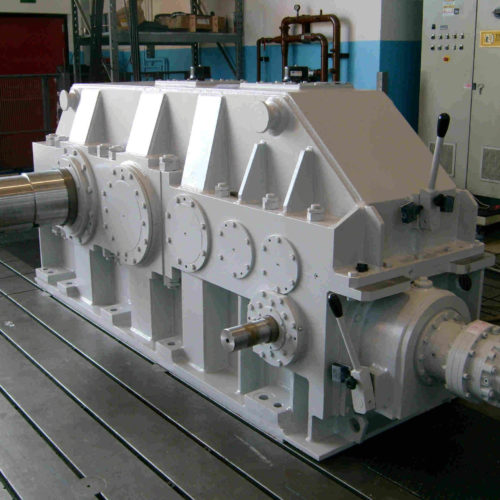

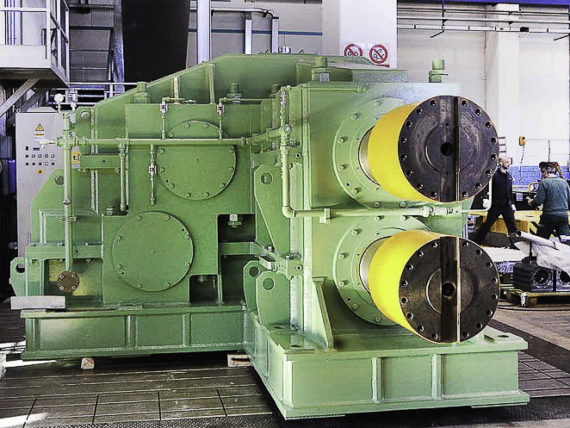

Afterwards, the pictures are presented that show the final acceptance (running test) in the presence and to the fully satisfaction of the customer.

English

English Italiano

Italiano Deutsch

Deutsch